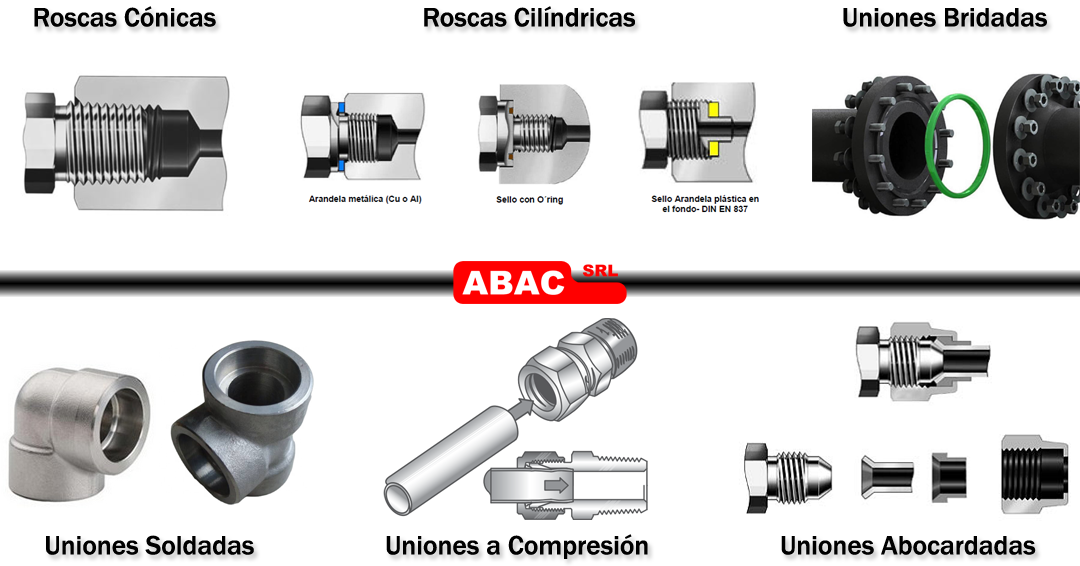

They are the mechanisms to join the parts of an installation, normally pipes with accessories or valves.

CONICAL THREADS

Designed not only to perform a mechanical joint, but also to produce a seal and retain pressures. Sealing takes place on the flanks of the threads.

CYLINDRICAL THREADS

There is no real interference between flanks, the sealing is not done in the same thread but externally, by using seal washers, o’rings or plastic gaskets.

FLANGED JOINTS

It joins two components of a conduction system, allowing it to be disassembled without destructive operations, thanks to a circumference of holes through which connecting bolts are mounted.

WELDED JOINTS

A type of welded joint called Socket Weld (SW) is commonly used. Valves should normally be disassembled before welding.

COMPRESSION JOINTS

They are joints of tubes with accessories or between tubes, where the retention of the same is carried out by a piece -metallic or not- that compresses the tube in its contour or periphery, without the need to previously deform the tube or reduce its section.

FLARE JOINTS

Pressurized metal joint, in which a conical widening is made at the end of the tube. They are widely used in hydraulics, refrigeration, etc., usually with carbon steel or copper tubes.