Maintaining working pressure in fluid systems is key to both operational efficiency and safety. Pressure regulators are typically responsible for maintaining accurate pressures, but working with high pressures or hazardous fluids can lead to accidental or unexpected pressure changes.

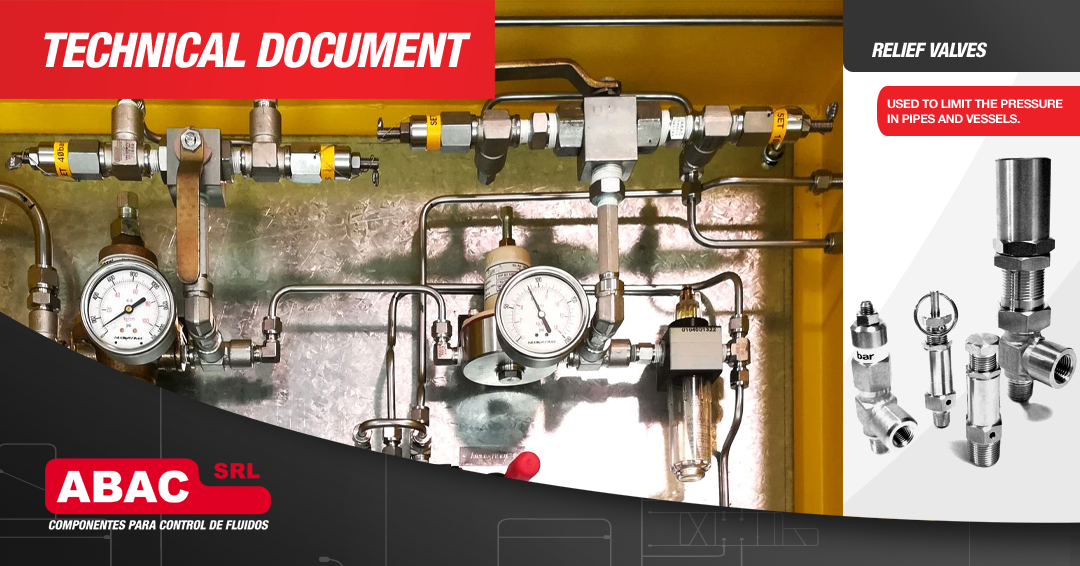

Relief valves are one of the fail-safes that should be included in the design of fluid systems. In practice, relief valves are set to a maximum allowable pressure; if the valve detects a higher pressure within the system, it will open and allow excess pressure to escape. The escaping pressure can be bled if the system fluid is toxic, or it can be allowed to escape to the atmosphere when it is safe to do so.

Why might relief valves be activated?

Procedural Error: Since fluid systems are operated by humans, they are inherently subject to human error. A technician may have opened the wrong valve, conditions may have been calibrated incorrectly, or the wrong model of pressure regulator may have been installed during routine maintenance.

Strong fluid systems training can help prevent these problems, but it’s still important to incorporate relief valves in case of operational errors.

Component Wear: Fluid system components naturally wear over time, especially those that handle harsh chemicals. Corrosion can cause premature wear if the material alloys are inadequate. In either case, component wear can compromise pressure control, so relief valves are necessary for safety.

Contamination: Pressure regulators can reliably reduce pressure to desired levels, but dirty or contaminated fluids can compromise their performance. Particles have the potential to compromise the regulator’s closure, improperly allowing pressure to pass through the seat, causing an increase in downstream pressure. In this case, a relief valve could release this unwanted pressure.

Power Loss: Some fluid systems may rely on electronic control of certain components for operation or pressure control. If the system experiences an unexpected power loss, compromising the ability of certain components to function as intended, relief valves will help control excess pressure.

ABAC offers relief valves with precise and reliable pressure relief, while ensuring tight shutoff over a wide range of pressures.

Models:

VAR Straight relief valve

• Pmax 300 psi | +info

VAA-D Angle relief valves (differential stem)

• Pmax 3,000 psi | +info

VAA-B Angle relief valves (balanced stem)

• Pmax 3,000 / 5,000 psi | +info

VAAH High pressure angle relief valves

• Pmax 15,000 / 20,000 psi | +info

Custom contact:

📧 ventas@abac.com.ar

📞 (+54 9 11) 3221-9356 / 9357