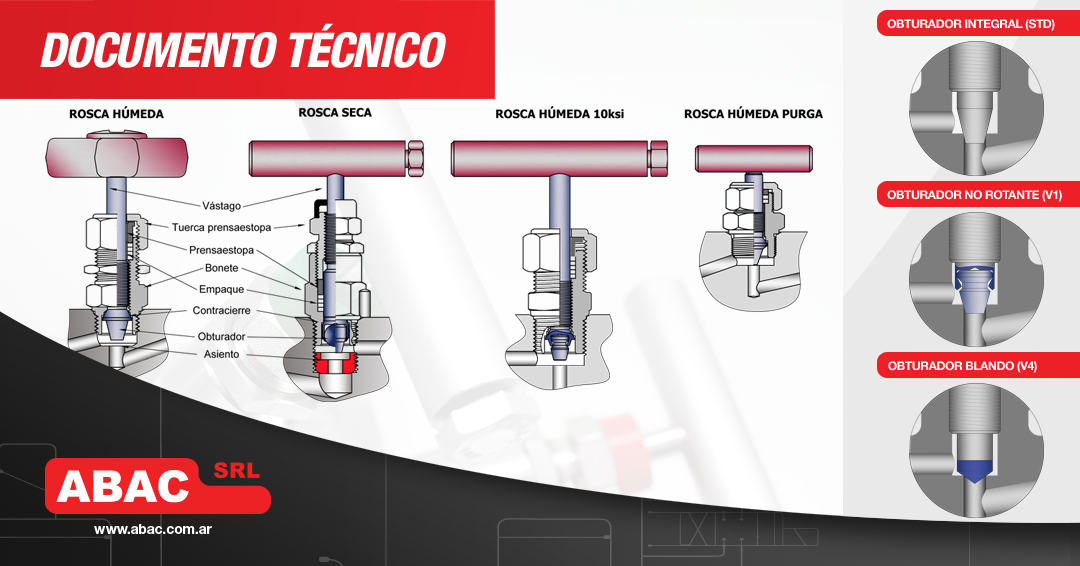

Most ABAC Manual Valves and all ABAC Manifolds have threaded bonnets on their bodies. These seal any process leaks with a metal-to-metal seal, without joint ring.

We have 2 models of bonnets for pressures up to 690 bar: Wet Thread and Dry Thread. The difference is that in dry thread bonnets, the packing is below the thread, preventing the process fluid from coming into contact with the stem thread.

The stems are made of stainless steel in all the models, with a counterlock, which avoids the risk of expulsion and isolates the packing from the process pressure. While their threads are laminated and lubricated to avoid galling and reduce operating torque.

Know its main characteristics:

WET THREAD BONNET

• Repacking under pressure

• Different types of plug

– One piece steam, for standard applications.

– Type V1. Hard, non rotating point. Recommended for dry gases, steam, or when looking for a longer service life.

– Type V4. Soft tip stem. Recommended for tight seal with lower torque.

• Available in Needle Valves and Gauge Valve, up to 6000 psi.

WET THREAD BONNET 10ksi

• Reinforced housing thread.

• Non-rotating hard tip stem that ensures long life even in extreme conditions.

• Available in Needle Valve versions for 10,000 psi.

BLEEDING WET THREAD BONNET

• Needle type shank with counterlock, repackable under pressure.

• Available in 1/4″NPT Block and Bleed Valve and Manifolds, up to 6000 psi.

DRY THREAD BONNET

• Packing under the thread of the stem that keeps it isolated from the process fluid. Adjustable in service.

• Plastic cap to retain lubricant and to prevent contaminant access.

• Non-rotating plug.

• Available in Multi-port Block Valve, Block and Bleed Valve and Manifolds, up to 6000 psi.

DRY THREADED BONNET 10ksi

• Reinforced housing thread.

• Non-rotating hard tip stem that ensures long life even in extreme conditions.

• Available in Block and Bleed Valve versions, for 10,000 psi.