Experience has shown us that the safety valve is often confused with the relief valve, and the reality is that they are for different applications.

Safety valves are recommended for use in steam and gases, when a device capable of instantaneous pressure relief is desired. Generally this type of valve has a safety device with a “POP ACTION” effect (instantly opening or closing action). This resource is not available in relief valves.

Relief valves are recommended for use in liquids, compressed air and even some inert gases, when it is desired to automatically and gradually make small pressure compensations (relief), with the valve opening or closing gradually as the pressure of the system increases or decreases, respectively. These valves do not meet the ASME code or other codes as a safety valve.

specializes in relief valves, which offer precise and reliable pressure relief, while ensuring tight closure over a wide range of pressures.

When the fluid pressure exceeds the valve’s SET (that is, the resistance offered by the spring), the valve opens, allowing the flow to be discharged through the outlet channel. In general, this setting value is adjustable, within limit values for each range.

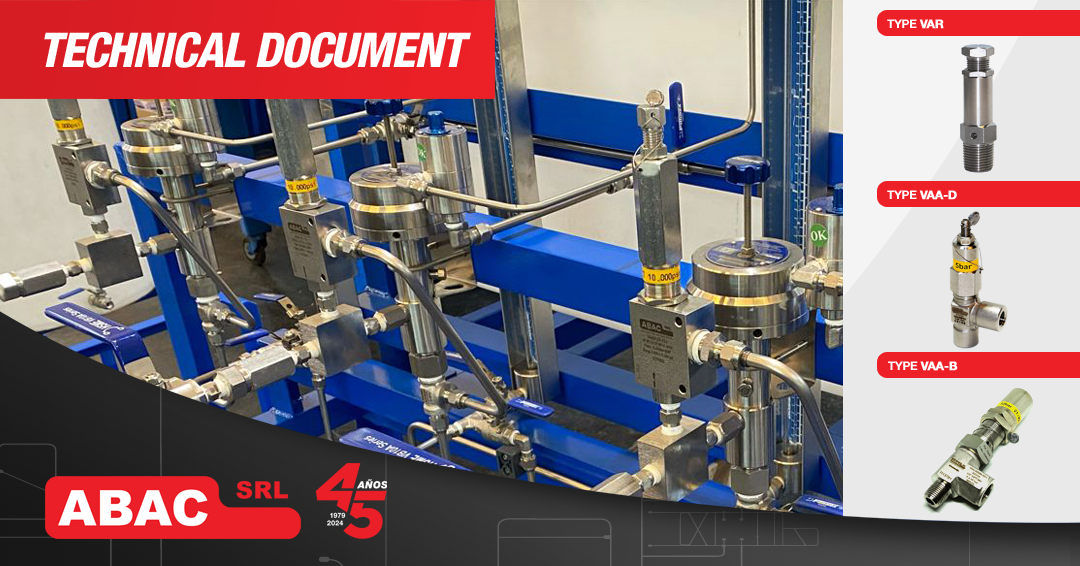

Models:

Straight relief valve

– Angle relief valves (differential stem)

– Angle relief valves (balanced stem)

High pressure angle relief valve

In , – and , the set point pressure is defined as the difference between the inlet pressure and the outlet pressure. They are designed to discharge to the atmosphere, without back pressure.

In – , however, the set point value is independent of the back pressure at the outlet, and can operate in environments with outlet pressures similar to the inlet, such as in CNG storage systems.

For more information, visit our fluid control accessories catalog.

And the technical sheet of the high pressure angle relief valve.